Systematically recorded

emission measurements.

- Front Page

- Our offering

- Power engineering

- Services/testing

Electromagnetic

emission measurements

Immissions occur during the operation of electrical equipment and are caused by magnetic and electric fields. In transformer stations, only the immission of the electromagnetic field is of interest. The determining components in transformer stations are therefore the combination of low-voltage switchgear, the low-voltage connections coming from the transformer and the low-voltage cables leading out of the transformer station.

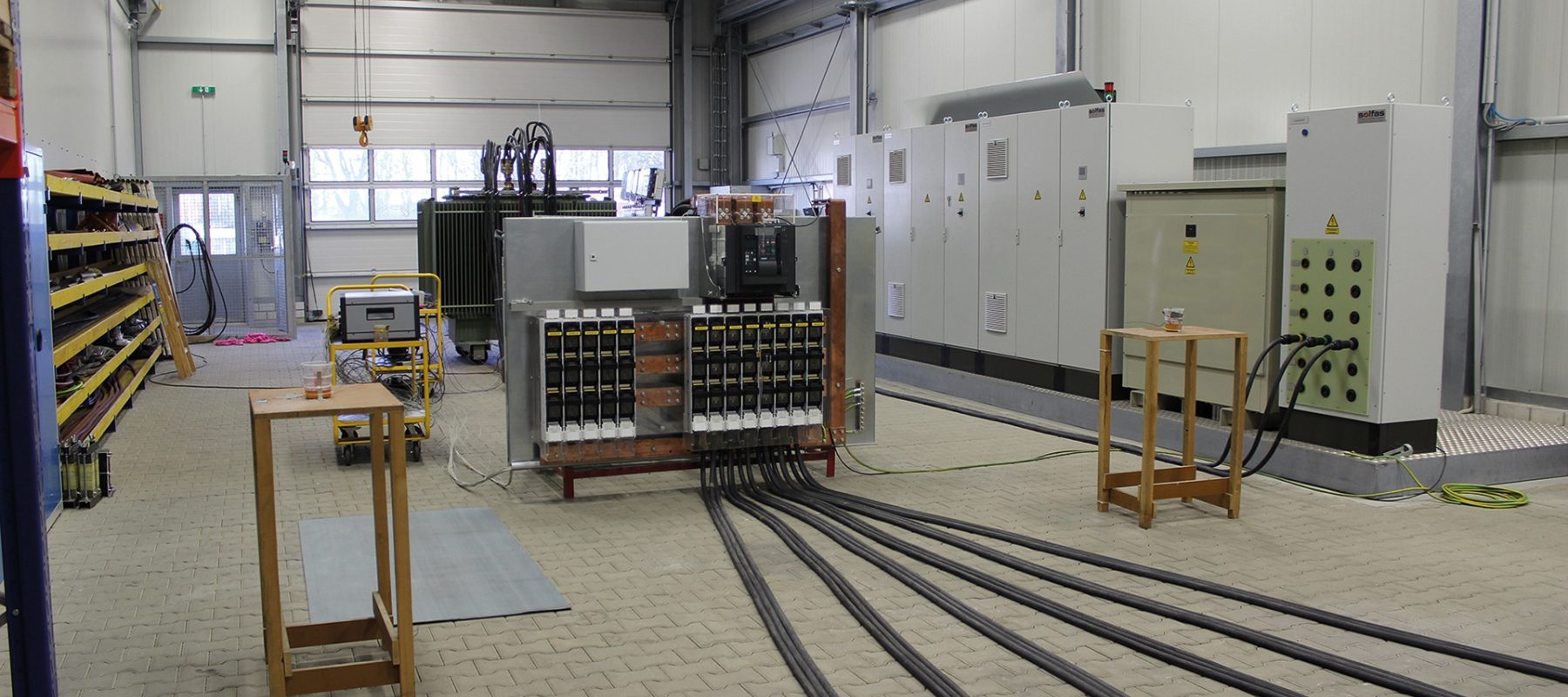

In our in-house test facility at our Ahlhorn site, we carry out EMC tests for all types of transformer stations and, if necessary, derive the necessary structural measures to comply with the specified limit values of the 26th BimSchV.

Great climate thanks to

heating measurements

Since the increased emergence of compact station types, our experts have been conducting numerous heating measurements in recognised test fields for over 25 years to guarantee our customers optimum operational reliability. For our own development tests and as a service offering, we also have our own in-house heating test field for measurements on transformer stations up to 4,000 kVA.

As a renowned manufacturer, we test all our transformer stations extensively for electrical, thermal and mechanical stresses. This is particularly important when new circumstances place higher demands on the electrical engineering and operational safety of the stations, for example in the field of renewable energy generation, charging infrastructure or digital local network stations.

With regard to heating, the following key aspects must be taken into account for transformer stations:

- Correct dimensioning of the ventilation elements for heat dissipation, mainly determined by the power loss of the transformer and the low-voltage components, in order to avoid unwanted shutdowns.

- Correct electrical engineering design, e.g. of the transformer used with regard to its power loss, which, similar to the free ventilation cross-section, has an important influence on the enclosure class (DIN EN 62271-202/VDE 0671-202) of a transformer station.

- The right station concept for the professional placement of measurement and remote control technology within the permissible ambient conditions.

- Prevention of condensation (occurrence of condensation) inside the station under unfavourable climatic conditions, so that no corrosion of the installed electrical components can occur. The standard use of our own GRÄPER lightweight concrete significantly reduces condensation.

Uncompromising safety:

Arc fault protection

Our stations are designed to meet all requirements for pedestrian and operator protection in accordance with DIN EN 62271-202.

To this end, our engineers have been successfully conducting arc fault tests in accredited test fields at our transformer stations for over 40 years. These active tests prove that in the event of a fault in the medium-voltage switchgear, there can be no harm to operating personnel or passers-by.

As one of the first manufacturers to do so, we have already successfully tested numerous SF6-free medium-voltage switchgear assemblies in our transformer and transfer stations in view of the new F-gas Regulation, thereby contributing to environmental protection and sustainability.

Electrical installation

Our stations

Our specialists are able to manage your project from start to finish. This includes the following stages:

- Inspection of the local conditions of the project

- Planning and project management of the technical equipment

- Project-related quotation

- Purchase of the appropriate electrical components

- Electrical engineering of the project by qualified personnel

Type testing

Low-voltage distribution

At GRÄPER, we have been successfully carrying out the tests required for our low-voltage distribution systems for many years as part of our quality assurance process. We test our switchgear assemblies in accordance with DIN EN 61439 both in accredited test facilities and in our own heating test facility in Ahlhorn. In doing so, we ensure that all components do not exceed their maximum operating temperatures, that short-circuit and surge current resistance is guaranteed and that all contact temperatures are complied with.

Better safe than sorry:

Partial discharge measurements

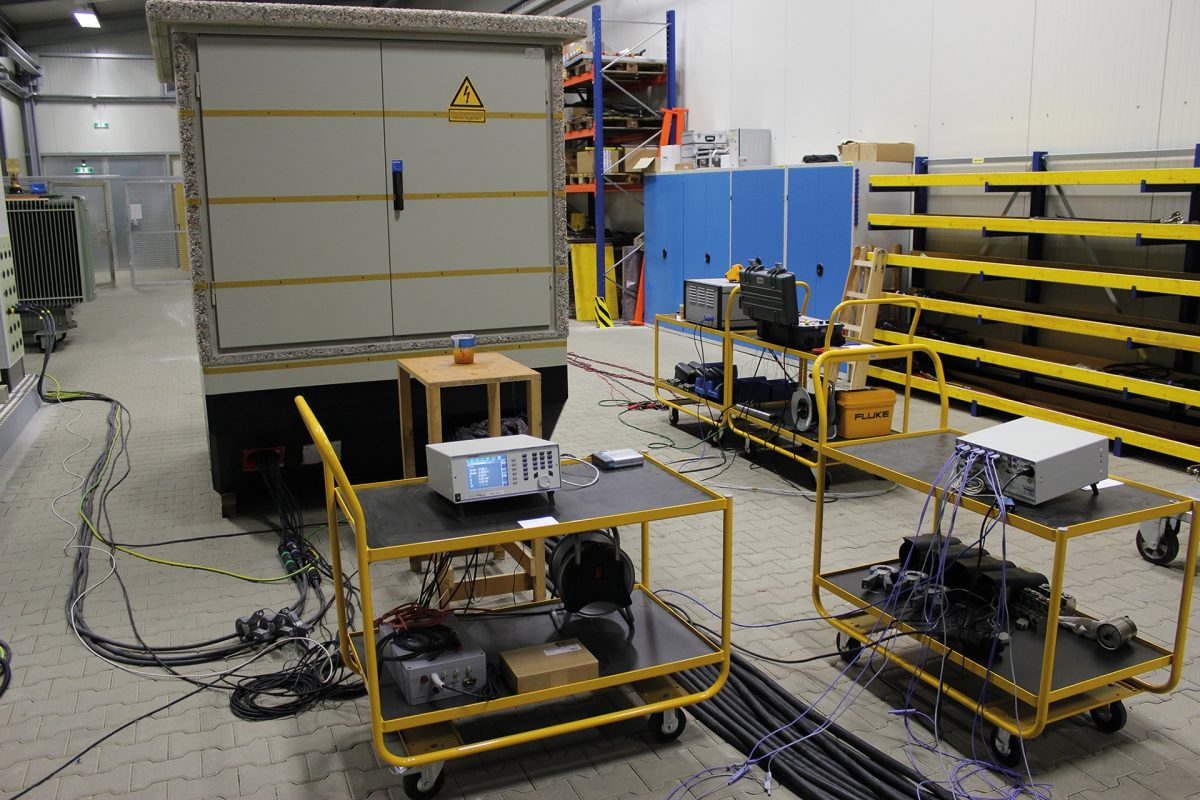

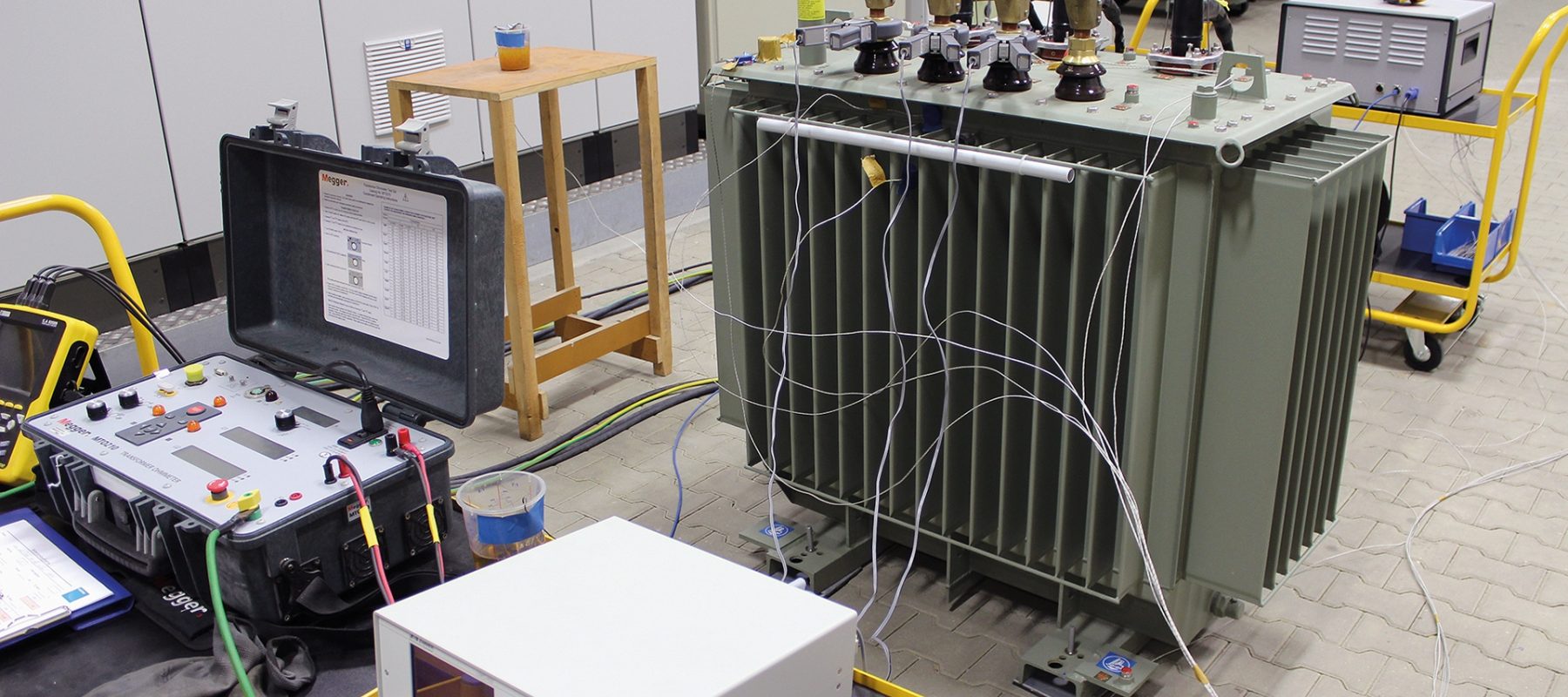

As a station manufacturer, we have our own partial discharge test fields (PD test fields) at all production sites. The fields are equipped with a high-voltage generator (100 kV) and a computer-assisted PD measuring device.

Partial discharge measurement technology provides us with a powerful tool for fault location and quality assurance of electrical equipment, which makes a decisive contribution to the operational safety of transformer stations.